HAZOP

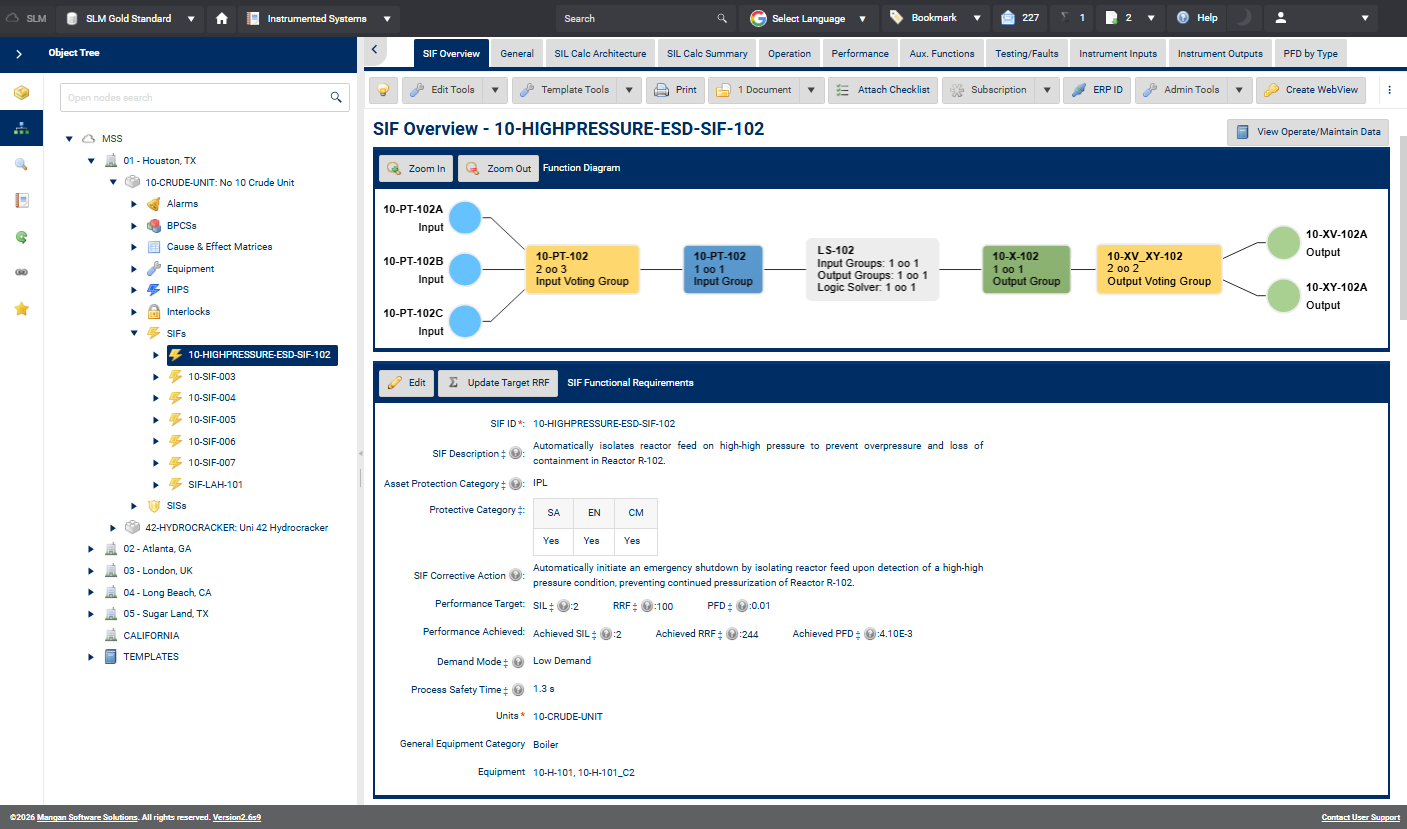

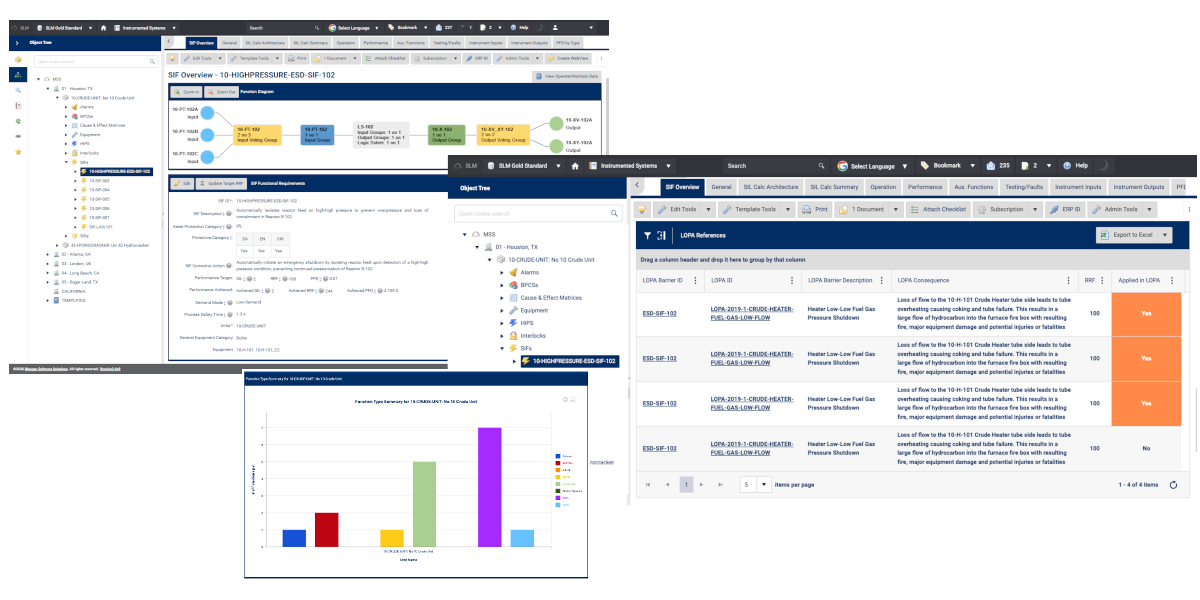

Control Your Safety Instrumented Systems with Confidence

Design, verify, and manage every SIF in one structured platform — from LOPA targets to proof test optimization — fully aligned with IEC 61511.

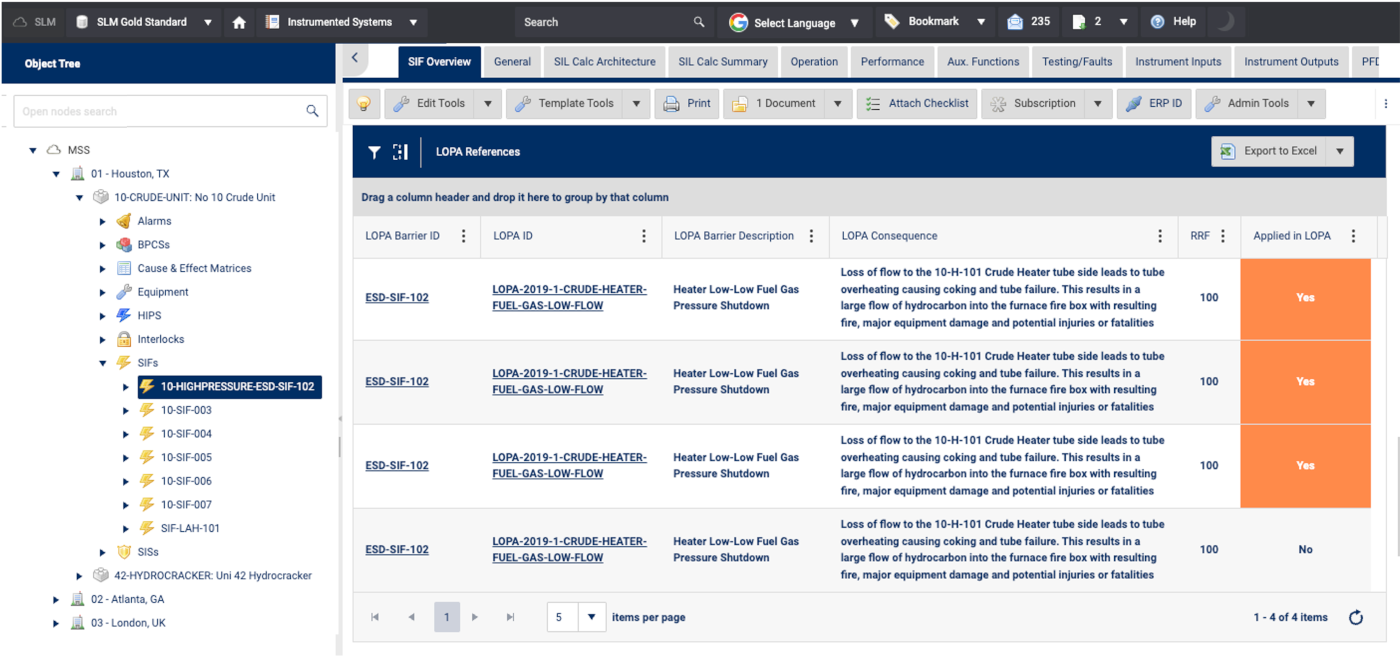

Build and Control Your Full Protection Layer Architecture

Design, structure, and manage every protection layer in a centralized, traceable environment.

Model complete Safety Instrumented Functions alongside other Independent Protection Layers — including Alarms, BPCS safeguards, Fire & Gas systems, and Interlocks — with full architectural visibility and Safety Requirement Specification Documentation.

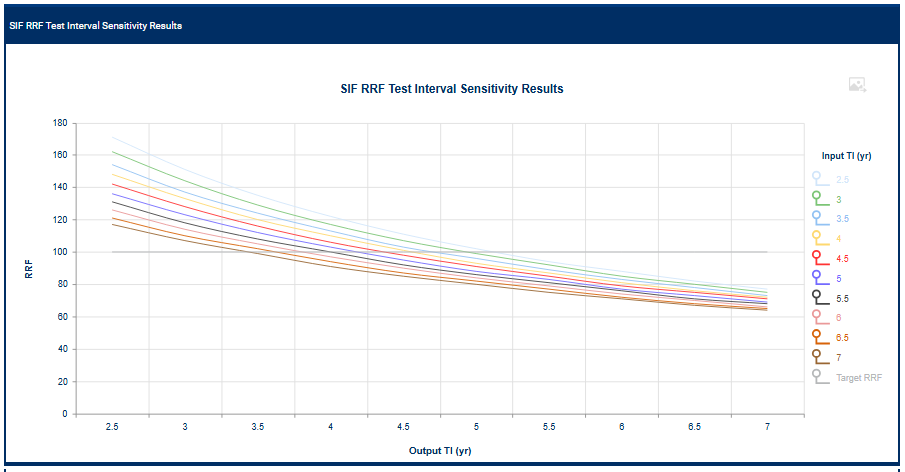

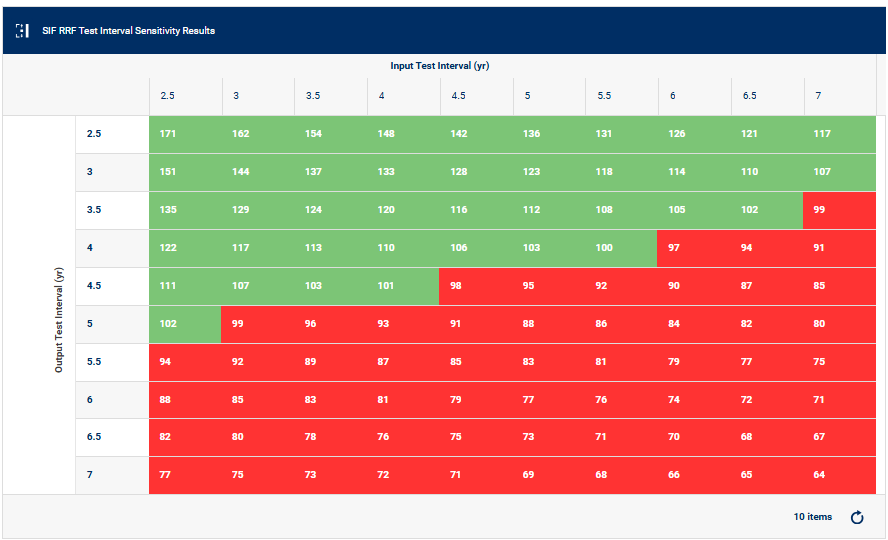

Proof Test Interval Optimization & Risk Insight

Reduce unnecessary maintenance while protecting safety margins. By modeling the real impact of proof testing frequency, you gain visibility into where you are over-maintaining, under-maintaining, or operating at unnecessary risk.

Build a Safer System from the Start

BLOG & ARTICLES

Stories that Drive Innovation

Discover how our software solutions enable smarter decision-making, operational excellence, and compliance across the world’s most complex industrial environments.