JUST BEING SAFE IS NOT ENOUGH

Your facility is Safe.

Is it SLM® Safe?

SLM® Safety Lifecycle Manager. The only TUV Certified Solution that digitally manages the entire IEC61511/61508 Safety Lifecycle.

The Platform

The SLM Platform:

The Power Of Digitization

The #1 selling cloud-based platform engineered to solve your toughest Process Safety and SIS Lifecycle Management challenges.

OUR SOLUTIONS

Elements of the Safety Lifecycle

SLM® breaks down the phases of the IEC61511 Lifecycle into 5 Core Elements to help manage the tactical phases of the Safety Lifecycle Journey

Hazard and Operability Study (HAZOP)

The HAZOP Module modernizes legacy PHA/HAZOP tools with an intuitive UI, faster studies, standardized workflows, and instant reporting—reducing expert costs and improving risk insights.

Learn More

Layer of Protection Analysis (LOPA)

The LOPA Module streamlines LOPA and IPL assessments with intuitive worksheets, real-time risk monitoring, and instant reporting.

Learn More

Safety Systems (SS)

Safety Systems centralizes process safety protection layers—instrumented systems, non-instrumented safeguards, and relief systems.

Operation and Maintenance (OM)

The Operate/Maintain Module tracks the performance, history, and reliability of protective systems and devices, using test procedures and event data to identify trends and issues.

Learn More

Functional Safety Assesssments (FSA)

Independent validation. Complete lifecycle confidence. The FSA Element enables thorough reviews at key milestones to ensure your safety lifecycle activities comply with IEC 61511 requirements.

Learn More

One Platform. Total Safety Lifecycle Management.

The SLM Platform connects every discipline of functional safety, enabling teams to collaborate across HAZOP, LOPA, Instrumented Systems, and more. With centralized data, automated reporting, and cloud scalability, it ensures full IEC 61511 and ISA 84 compliance while streamlining safety operations.

- Unified Safety Modules: Integrate HAZOP, LOPA, Instrumented Systems, and Barrier Assurance in one platform.

- Data-Driven Decision Making: Harness analytics to identify, predict, and mitigate risks.

- Cloud-Enabled Access: Access secure, real-time insights from anywhere, anytime.

- Regulatory Confidence: Built to align with global functional safety standards.

COMPANY IN NUMBERS

Trusted Worldwide

Cost Savings in First Year

0

+

Average savings per process action compared to Sharepoint

0

$

Global Offices

0

Estimated Revenue

$

0

M

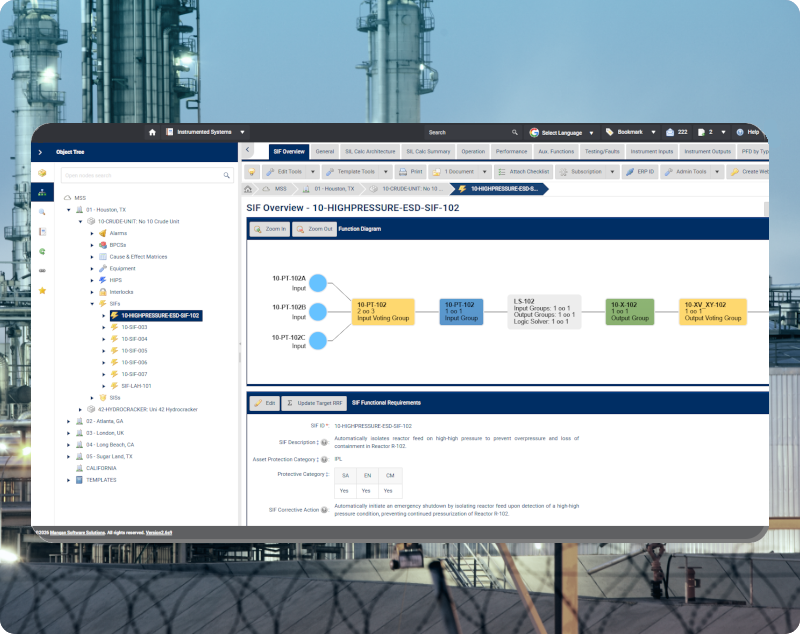

Visualization Through Digitization

We focused on making an interface as easy to use as it is on the eye. Stunning new visualizations and an interface engineered to provide the ultimate user experience. View your Safety Instrumented Systems, Safety Instrumented Functions, and Barrier Management Systems and their components in our interactive, graphical layout.

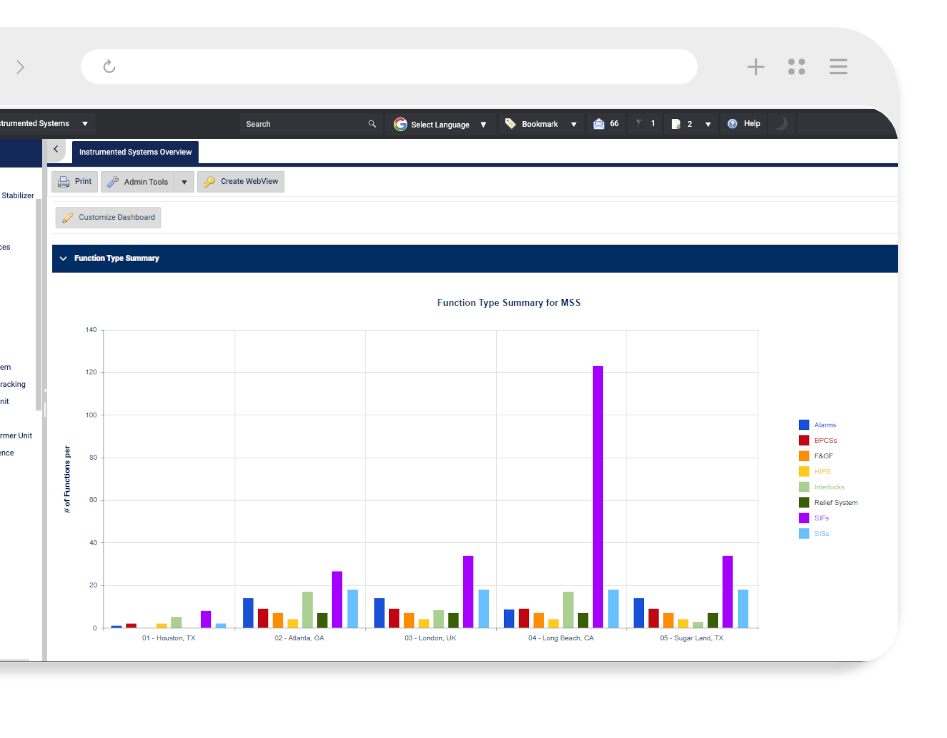

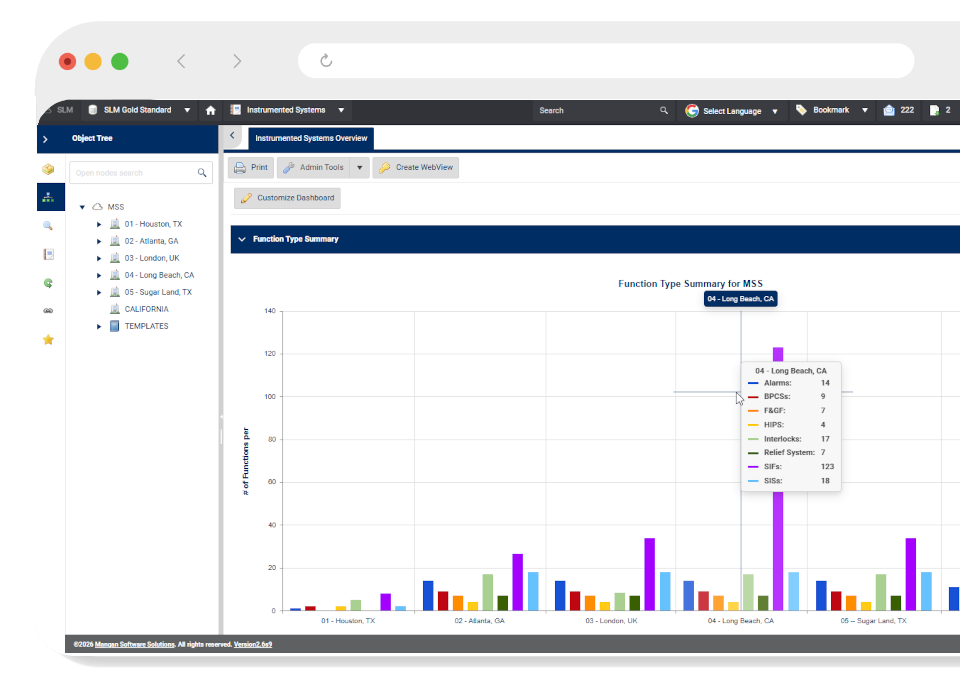

Transform Process Safety Information Into Process Safety Intelligence

For most organizations, current systems struggle to report lagging indicators on failures and incidents to Safety Instrumented Systems and Independent Protection Layers. The SLM Platform’s Tier III metrics features and analytics allow our users to leverage their existing data to avoid major incidents, improve plant availability and optimize operating conditions.

With SLM’s Tier 3 Metric features, users have the opportunity to achieve operational excellence and continuous improvement in safety through:

Informed Risk Mitigation Strategies: Confidently deploy resources towards high-risk scenarios and ineffective prevention barriers

Reduced cost structure: Collect meaningful performance information through standardization and efficiency without relying on 3rd-Party Contractors

Performance Monitoring: Evaluate the performance of the SIS/SIF against its safety design.

Safety Lifecycle Management: Ensuring that Instrumented IPLs are Managed Effectively and Efficiently

Tier 1

Events of Greater Consequence

Tier 2

Events of Lesser Consequence

Tier 3

Challenges to safety systems

Tier 4

Operating Discipline & Management System Performance Indicators

Imagine SIS Lifecycle Management With The Data

Implementing functional safety requirements for your facility or Safety Instrumented System project has to be easier. With so many spreadsheets, software tools and process safety information spread everywhere, the challenge of SIS Lifecycle Management is daunting. The SLM Platform gathers all of your functional safety and process safety information into one robust system, giving you one single source of truth.

OUR INDUSTRIES

Industries We Serve

Oil & Gas

- Process safety management

- SIS lifecycle compliance

- LOPA & PHA integration

Chemical

- OSHA PSM compliance

- Batch automation

- Asset reliability tracking

Pharmaceutical & Biotech

- GMP validation

- 21 CFR Part 11 compliance

- Equipment qualification

Power & Utilities

- Control system safety

- Maintenance optimization

- Change management

Mining & Metals

- Predictive maintenance

- Environmental monitoring

- Safety automation

Food & Beverage

- Sanitation validation

- Batch traceability

- Quality assurance

Advanced Reporting And Data Templates

With over 150+ Reporting and Data Visualization Templates that our customers can extend or configure for their needs, SLM has the ability to help you stay on track and manage the SIS Lifecycle without the hassle of building reports. In addition SLM supports industry standard reporting frameworks like SQL Server Reporting Services to customize reports and data output for any organizational need.

built - in reports & templates

0

+

BLOG & ARTICLES

Stories that Drive Innovation

Discover how our software solutions enable smarter decision-making, operational excellence, and compliance across the world’s most complex industrial environments.